Purchase must see! Electronic component selection from entry to give up

2023-12-22 10:40:42

Electronic components as an important part of electronic products, its quality is the determining factor of product performance indicators, and procurement is the decision maker who decides to purchase materials.

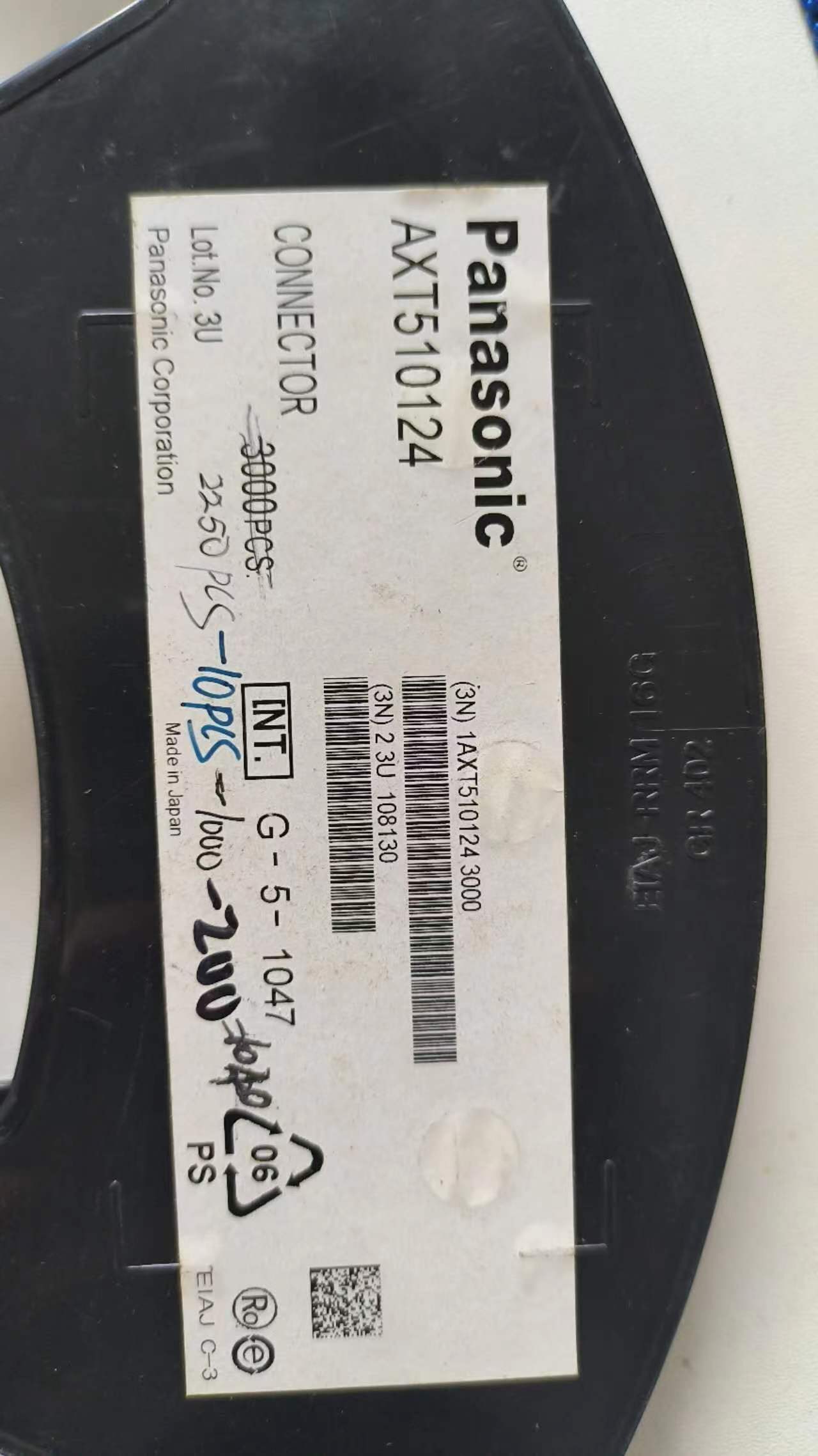

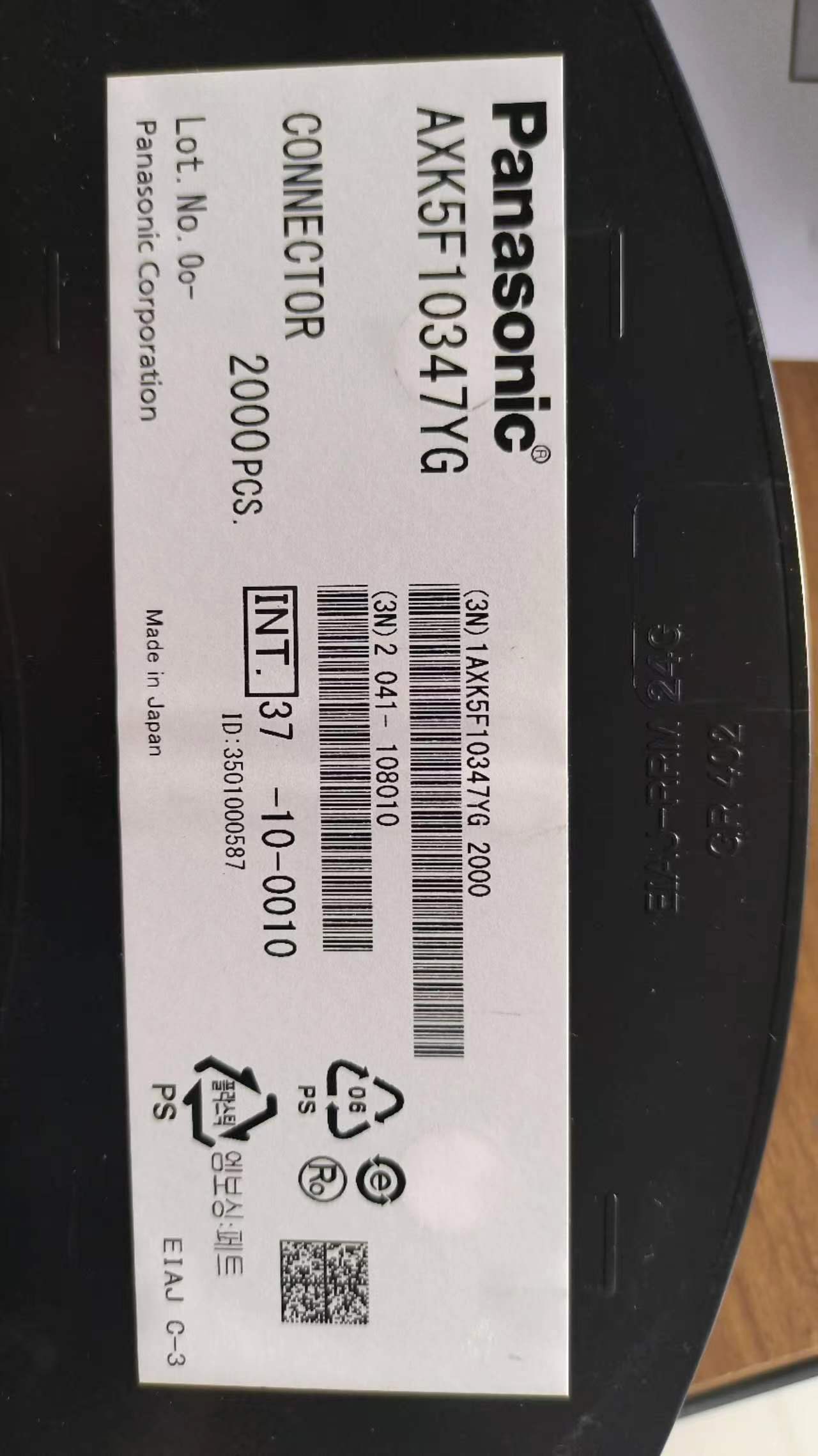

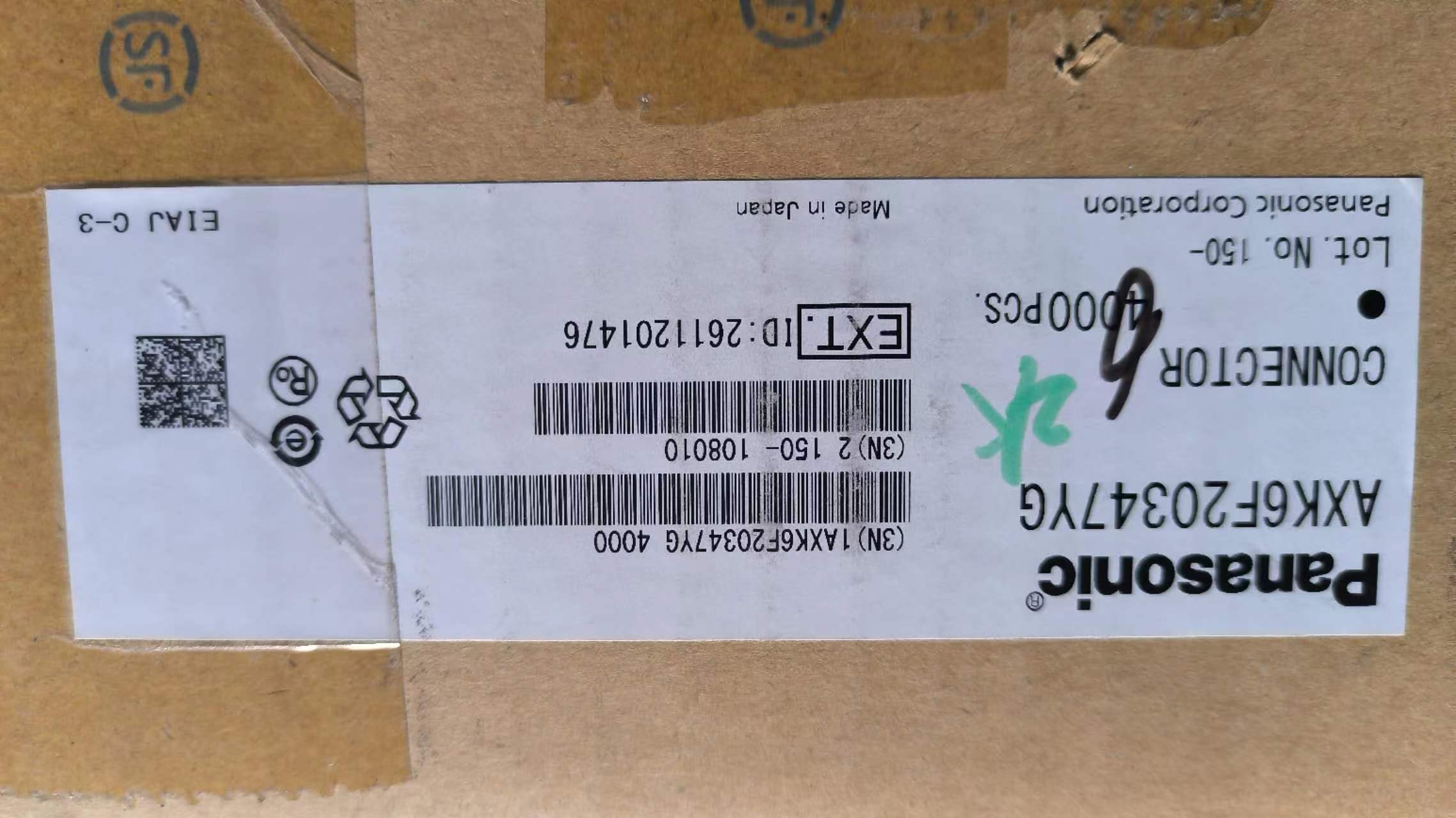

For the procurement staff, every step must be careful, otherwise the mistakes caused by the procurement process, resulting in the company's project progress delay or even major economic losses, the purchaser needs to bear the full responsibility.

To be honest, it is not easy to be a buyer, and it takes more time to study and practice. After all, the components market is mixed, the market is deep like the sea, and the slightest mistake may fall into the minefield. Electronic material procurement should not only cooperate with electronic design engineers to complete the required work, but also understand the basic principles of selection, in order to complete the task more professionally and better in the selection and replacement of electronic components.

Today, Daogo sorted out some electronic components selection experience to share, hoping to provide you with a little help in the procurement work.

Electronic components procurement In the selection of electronic components need to do the following work:

1. Understand project requirements: Buyers need to communicate with project management personnel to understand the key parameters, characteristics and working environment of the project, so as to determine the performance range, use conditions and reliability level of the required components.

2. Access to official information: Buyers need to refer to the relevant official information, such as data manuals, specifications, etc. for the required component brand and model to understand the basic parameters, electrical performance, mechanical size, working temperature, environmental requirements, etc.

3. Contact with suppliers: Buyers also need to contact with some reliable component suppliers, ask them about the required component model, price, delivery and other information, and compare the service and price of various suppliers, in order to choose the right supplier.

4. Sample test: Before selecting components, buyers need to carry out technical tests on the selected components, such as power consumption, stability, anti-interference ability, etc., to assess whether the components meet the requirements.

5. Evaluate the reliability of components: Buyers also need to consider the reliability and life of components in order to ensure the long-term use of components in the equipment is safe and reliable.

6. Confirm procurement: In the case of confirming that the selected components meet the demand, the buyer needs to place a purchase order with the supplier, and negotiate the price, delivery and other details with the supplier to ensure that the procurement can be completed on time and in good quality.

Basic principles of component selection:

a) Universality principle: If the selected components are widely used and verified, try to use less unpopular and biased chips to reduce development risks.

b) The principle of high cost performance: in the case of similar functions, performance and utilization, try to choose components with better prices to reduce costs.

c) The principle of convenient procurement: try to choose components that are easy to buy and have a short supply cycle.

d) The principle of sustainable development: try to choose components that will not be discontinued within a foreseeable period of time.

e) The principle of substitution: try to choose components that are compatible with more chip brands from pintopin.

f) Upward compatibility principle: try to choose the components used in the old products.

g) Resource saving principle: try to use all functions and pins of components.

Comprehensive consideration

01, easy to produce application reliability problems of the device

Devices that are sensitive to external stress

CMOS circuit: sensitive to static, latching, surge

Small signal amplifier: sensitive to overvoltage, noise and interference

Plastic packaging devices: sensitive to moisture, thermal shock, and temperature cycling

A device whose working stress is close to the maximum stress of the circuit

Power device: Power close to the limit value

High voltage device: The voltage is close to the limit value

Power supply circuit: voltage and current close to the limit (power supply)

High frequency devices: frequency close to the limit value (RF and high speed digital)

Ultra-large scale chip: power consumption is close to the limit value (especially high-power CPU, FPGA, DSP, etc.)

A device with high frequency and power

Clock output circuit: The highest frequency in the entire circuit, and to drive almost all digital circuit modules

Bus control and drive circuit: strong driving ability, high frequency

Transmitter in wireless transceiver circuit: power and frequency close to limits

02, the selection of components to consider the ten elements

1, electrical characteristics: in addition to meeting the functional requirements of the equipment, the components must be able to withstand the maximum applied electrical stress.

2. Operating temperature range: the rated operating temperature range of the components should be equal to or wider than the operating temperature range to be subjected to.

3. Process quality and manufacturability: the component process is mature and stable and controllable, the yield should be higher than the specified value, and the package should be compatible with the equipment assembly process conditions.

4. Stability: In the case of temperature, humidity, frequency, aging and other changes, the parameter changes within the allowable range.

(5) Life: the working life or storage life should not be shorter than the expected life of the equipment using them.

6. Environmental adaptability: Should be able to work well in a variety of use environments, especially such as hot flusher, salt spray, dust, acid rain, mold, radiation, high altitude and other special environments.

7. Failure mode: The typical failure mode and failure mechanism of components should be fully understood.

8. Maintainability: the convenience of installation, disassembly and replacement should be considered, as well as the required tools and proficiency level.

9. Availability: there is more than one supplier, the supply cycle meets the equipment manufacturing schedule, and can ensure the timely replacement requirements when components fail.

10. Cost: under the condition that it can meet the required performance, life and environmental constraints at the same time, consider using cost-effective components.

03. Failure mode and distribution

Failure mode: The failure form of the component, that is, how did it fail?

Failure mechanism: The reason for the failure of the component, that is, why the failure? The user of the component should understand the failure mode, if not the failure mechanism.

Failure mode distribution: If a component has multiple failure modes, the probability of each failure mode occurring is a prerequisite for failure analysis.

04, the characteristics of highly reliable components

Manufacturer certification: The manufacturer has passed the qualification certification of the authoritative department

Production line certification: Products can only be produced on certified special production lines.

Reliability testing: The product has undergone and passed a series of performance and reliability tests, 100% screening and quality conformance testing.

Process control level: The production process of the product has been strictly controlled, and the yield is high.

Degree of standardization: The production and inspection of products meet the international, national or industry general specifications and detailed specification requirements.

05, the preferred selection rules of varieties and models

1. Give priority to the selection of standard, general and serialized components, carefully select new varieties and non-standard devices, and minimize the variety specifications of components and the number of units.

2. List the components in the component preference directory.

3. Preferentially select products with mature device manufacturing technology, and select fixed supply units with long-term, continuous, stable, mass supply and high yield.

4. Preferentially select the manufacturer's products that can provide perfect process control data, reliability application guidelines or use specifications.

5. Under the premise of the same quality level, the device with high integration degree is preferred, and the discrete device is selected less.

06, the supplier should provide reliability information

Detailed specifications and standards: national military standard, national standard, line standard, enterprise standard

Certification: QPL, QML, PPL, IECQ, etc

Quality grade and reliability level: failure rate, life (MTTF), anti-static strength, anti-radiation level, etc

Reliability test data: acceleration and field, environment and life, recent and past, used test methods and data processing methods

Yield data: medium test (bare piece), total test (after packaging), etc

Quality consistency data: batch to batch, wafer to wafer, chip to chip, mean, variance, distribution

Process stability data: Statistical process control (SPC) data, batch production status

Processes and materials used: It is best to provide the main parameters of key processes and materials

User manuals and operating specifications: typical application circuits, reliability protection methods, etc

Process consideration

Take integrated circuits as an example:

Minimum lines: 0.35, 0.25, 0.18, 0.13μm

Substrate material: Si>SOI>SiGe>GaAs>SiC

Interconnect materials: Cu>Al (foreign advanced technology) Al>Cu (domestic existing technology)

Passivating material: SiN>PSG> Polyenimide inorganic > Organic

Bonding material: Au>Cu>Al(Si)

Circuit form: digital/mode separation > Digital/mode integration RF/BB separation >RF/BB integration

The relationship between CMOS chip yield and reliability

Yield (sometimes called quality) : The number of qualified devices found in a batch of devices during factory or aging screening.

Reliability: The number of failed components after more than one year of on-board time.

Generally speaking, the higher the quality and yield of the device, the better the reliability; However, the reliability of devices with the same quality and yield is not exactly the same.

SPC data: Characterization of pass rate

Statistical process control

Process accuracy and process stability is an important factor to decide the product yield and reliability, statistical process control (SPC, StaTIsTIcalProcessControl) data available to quantitative characterization.

The characterization parameters of qualified rate

yield: The percentage of qualified products in a lot.

ppm (partspermillion) : The number of unqualified products permillion products, suitable for product characterization with large batches, stable quality and high yield.

Process deviation and dispersion characterization:

The generation of nonconforming products mainly comes from the inevitable deviation and discretization of component manufacturing process, and the distribution of process parameters usually meets the normal distribution.

Packaging consideration

With pins: Parasitic inductor 1nH/mm/ pin (the shorter the better), parasitic capacitor 4pF/ pin

Leadless components: Parasitic inductance 0.5nH/ port, parasitic capacitance 0.3pF/ port

Comparison of parasitic effects of different package forms (from small to large parasitic parameters)

No pin Mount > Surface Mount > Radial pin > Axial plane parallel pin

CSP>BGA>QFP>SMD>DIP

The parasitic inductance of the capacitor is also related to the package form of the capacitor. The larger the ratio of pin width to length, the smaller the parasitic inductance.

02, conducive to reliability

The lead is extremely short: the distributed inductance and capacitance are reduced, and the anti-interference ability and circuit speed are improved

High mechanical strength: improve the ability of the circuit to resist vibration and shock

Good assembly consistency: high yield, small parameter dispersion

03, not conducive to reliability

Increased material mismatch: Some SMT components on ceramic substrates (such as some resistors, capacitors, leadless chip carrier LCC) do not match the thermal expansion coefficient of PCB substrate epoxy glass, causing thermal stress failure

Easy pollution: SMT components and PCB board is not easy to clean, easy to stay in the flux of pollutants, need to use special treatment methods

Surface mount is far more beneficial than harmful to reliability, currently accounting for 90% of the proportion

04. Comparison of packaging materials

Plastic package

Advantages: low cost (about 55% of ceramic package), light weight (about 1/2 of ceramic package), a large number of pins, weak high-frequency parasitic effect, easy to automate production.

Disadvantages: poor air tightness, moisture absorption, not easy to heat, easy to age, sensitive to static electricity.

Applicability: Most semiconductor discrete devices and integrated circuit conventional products.

Ceramic package

Advantages: good air tightness, strong heat dissipation (high thermal conductivity), good high-frequency insulation performance, large power, high wiring density.

Disadvantages: High cost.

Applicability: Aviation, aerospace, military and other high-end markets.

Metal package

Advantages: good air tightness, strong heat dissipation, electromagnetic shielding capability, high reliability.

Disadvantages: High cost, limited number of pins.

Applicability: Small scale highly reliable devices.

It is usually called a non-airtight package, and ceramic and metal are airtight packages.

Moisture absorption problem

The epoxy resin material used in plastic packaging has moisture absorption, and moisture is easily adsorbed on its surface.

Water vapor can cause creep of the plastic sealing material itself, and if it invades the inside of the chip, it can lead to corrosion and surface contamination.

Air tightness problem

The difference between the thermal expansion coefficient of plastic tube shell and metal lead frame, semiconductor chip and other materials is much larger (compared with ceramic and metal tube shell)→ temperature change will produce considerable mechanical stress at the material interface → gap at the interface → resulting in air tightness deterioration of water vapor accumulation at the gap → rapid vaporization and expansion when the temperature rises → interface stress further increases → it is possible to make plastic Seal burst (popcorn effect)

The temperature of PCB reflow welding can rise to 205 ~ 250℃ within 5 ~ 40s, and the rise gradient can reach 1 ~ 2℃/s, which is easy to produce the above effect.

Temperature adaptability problem

The glass transition temperature of the plastic sealing material is 130 ~ 160℃, and the plastic sealing material will soften after exceeding this temperature, which also has an adverse effect on the air tightness.

The temperature range of commercial plastic encapsulation devices is generally 0~ 70℃, -40~+85℃, -40~+ 125℃, and it is difficult to reach the military temperature range of -55~+125℃.

33 Golden Rules of Electronic Component procurement:

1. Prevent suppliers from quoting in small units of measurement, thereby reducing your sensitivity to price.

2. The exact number of decimal points on the quotation should be determined according to the quantity purchased.

3. When analyzing and reviewing quotations, use the currency unit you use most often or are most familiar with. If RMB appreciates, what price should we quote for imports? In foreign currency; If the RMB depreciates, what price should we use for imports? Local currency)

4. From the point of view of quotation unit and method, we should try our best to quote in the most favorable way for us.

5. The quotation of the split should pay special attention to the quotation strategy and way of breaking the whole into pieces. (The so-called breaking into pieces is that there is a decimal point carry in each part of the split offer. Suppliers do a little more here, a little more there, and the whole thing goes up. This is also a problem that can easily occur in the "price list of supporting products" which is subdivided into many items.)

6. Quote according to the purchaser's cost structure. (When purchasing large quantities of products, the format of the quotation sheet should be done in accordance with the requirements of the procurement, that is, the supplier should be asked to quote in accordance with our unified quotation method and quotation format, including the cost calculation method should be unified in accordance with our requirements, which is very important. This will help you analyze supplier quotes and costs.

7. Pay special attention to the fact that when the supplier explains the offer, he will try to increase your understanding of the value, so that you will naturally accept his price.

8. Procurement should also be good at crying poor, if you are always in front of suppliers to thank the attention to procurement practitioners wechat public number put a look of wealth, it is certainly difficult to get a more favorable price.

9. When you need a quotation from a supplier, you must learn to hide your procurement purpose and grasp the needs of procurement. If you tell the supplier what you want in advance and then ask for a quote, the price may be too high. That means it's hard or impossible to get the price you want.

10. To analyze the source of the supplier's raw materials, and improve the cost impact of non-normal factors in the procurement cost model. This helps us analyze the true cost of suppliers.

11. It is necessary to pay attention to the problem that the supplier uses the positive tolerance quotation to calculate the cost and the negative tolerance production. In other words, sometimes when the supplier calculates the procurement cost, all of them are calculated according to positive tolerances, but in fact, all of the products are produced with negative tolerances. The condition of the mold should be evaluated periodically.

12. Analyze the vendor's proposal for pitfalls. The supplier's suggestions are valuable, but there may be conspiracies against us, we must distinguish the "good intentions" of the supplier.

13. The quotation should specify the brand of the raw material supplier, and the replacement should go through the procurement certification. This can not only avoid the supplier "shoddy", but also control the cost and ensure the quality.

14. The review of raw materials should not be relaxed, especially the split offer. Usually suppliers put "water" on raw materials, procurement is also easy to accept, and many procurement in the supplier's raw material cost analysis of this input resources, spend less time, especially the price of raw materials change greatly, suppliers often take the opportunity to raise prices. The raw materials in the supplier's quotation cannot move, which is a wrong view.

Fifteen. Suppliers usually quote the parts of procurement that are most familiar with the cost or the most transparent part of the market. Thank you for paying attention to the wechat public accounts of procurement practitioners to let us think that the quotation of suppliers is real and cheap, and gain the trust of procurement in the quotation of suppliers. Instead, bid up the least familiar parts of the purchase or the parts of the market that are not transparent.

16. Pay attention to the flexible items in the quotation. Supplier quotation often hides a lot of flexible calculation cost items, such a quotation strategy, suppliers can often succeed in obtaining large profits in the future. If you do not pay attention to procurement, you will pay unnecessary costs. Preferably items that reduce the cost of flexible computing.

17. Pay special attention to the cost loss caused by container residues (impurities). In addition to the problem of gas container residue, in fact, the glue that is constantly recycled also has a similar problem.

18. Attention should be paid to the disposal of the waste material generated by the production of the product, and the value generated by it should also be assessed as part of the supplier's profit, or against the cost.

19. A comprehensive review should be conducted to track possible tax changes on purchased products. (Taxes are often double-counted.)

20. Quotation analysis and cost analysis should be combined with supplier factory analysis. Many purchasing managers believe that purchasing to the supplier's factory is a waste of time, and there are travel costs. The most important thing is to purchase to the supplier's factory, which will be easier to be "fixed" by the supplier. Thank you for paying attention to the procurement practitioners wechat public number this view makes many of the company's procurement staff unable to do more professional. Because they have no idea how the products they buy are produced, let alone how much the suppliers cost to provide them.

Twenty-one. Pay special attention to the problem of suppliers cutting corners. The supplier can make whatever you want for whatever you want, just by cutting corners. Low price does not mean low cost, quality and quantity is very important, so we should constantly track and analyze the changes in the quality and quantity of purchased products.

Twenty-two. For the production of plastic parts, casting parts, etc., the ratio of old and new materials should be specially controlled. We might even consider unannounced audits of supplier integrity. Check whether the supplier is producing according to the technical standards specified in the purchase.

Should pay attention to the analysis, the finished product can not be accounted for the cost or material consumption of the project.

24. In order to understand the learning curve and scale effects of supplier costs, multi-stage pricing should be used. The more labor-intensive the product, the greater the scope for subsequent cost reduction; The more in the mass production stage, the cost is likely to decline in a learning curve, and the learning curve even lasts a long time. In addition, scale effects are also likely to be an important factor in cost changes. Through the analysis of learning curves and economies of scale tracking and analysis, procurement costs can be automatically reduced.

Twenty-five. Usually, 20% of the items in the quotation often account for 80% of the cost, 30% of the items account for 15% of the cost, and 50% of the items account for only 5% of the cost. So we need to focus on the items that account for the largest share of the total cost.

Twenty-six. Integer items, suppliers are likely to be rough estimates, very rough, should be concerned. In addition, costs such as sales are likely to have economies of scale and need to be linked to the volume of purchases when allocating costs.

27. It should be noted that the supplier uses the psychometric quotation method, which is manifested in two forms: the first form is that the supplier creates a feeling that the quotation is calculated; The second form is that the supplier quotes the price lower than our certain psychological price, so that the procurement is easier to trust and accept. Thank you for paying attention to purchasing practitioners wechat public number

28. The so-called proof provided by the supplier is likely to be second-hand data and information, and do not stop analyzing the supplier's cost because of the proof unless you are really confident that there is no problem.

29. Analyze the rate of allocation of expenses as much as possible, not the addition, subtraction, multiplication and division of expenses. Because distribution rates are relatively easy to compare with industries and suppliers. As mentioned earlier, suppliers often make a fuss about raw materials, in fact, the costs of various projects, including direct wages, manufacturing costs, administrative costs, and financial costs are also of great importance.

Thirty. Logic errors are a problem that we need to pay special attention to, especially for complex projects. Suppliers often make this mistake on purpose.

Thirty-one. The purchase quantity and the economics of the mold should be evaluated.

Thirty-two. The supplier should evaluate the match of the mold developed by the supplier with other suppliers.

Thirty-three. The leverage point of the quotation should be analyzed emphatically, and it should be calculated every ounce.